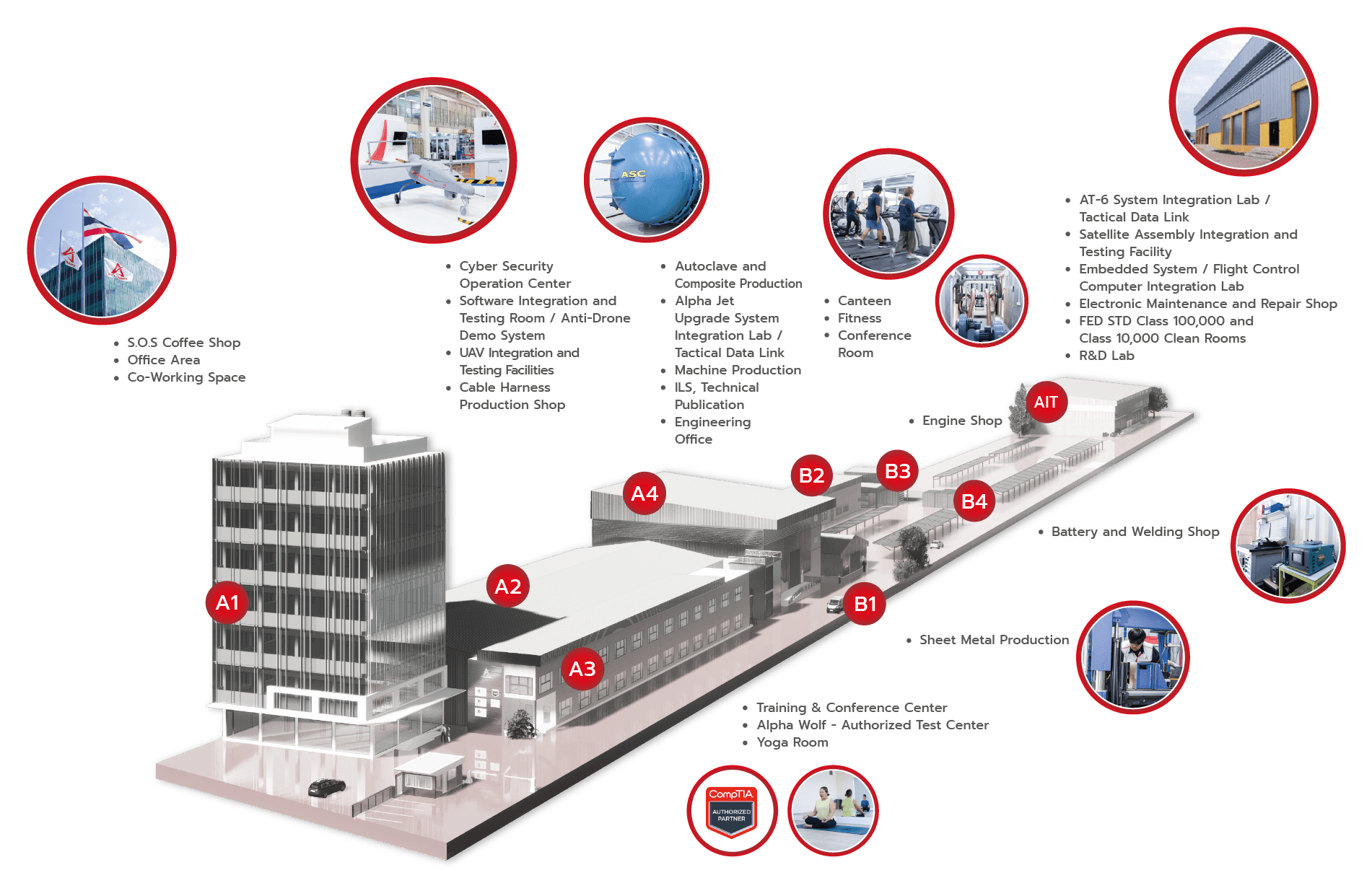

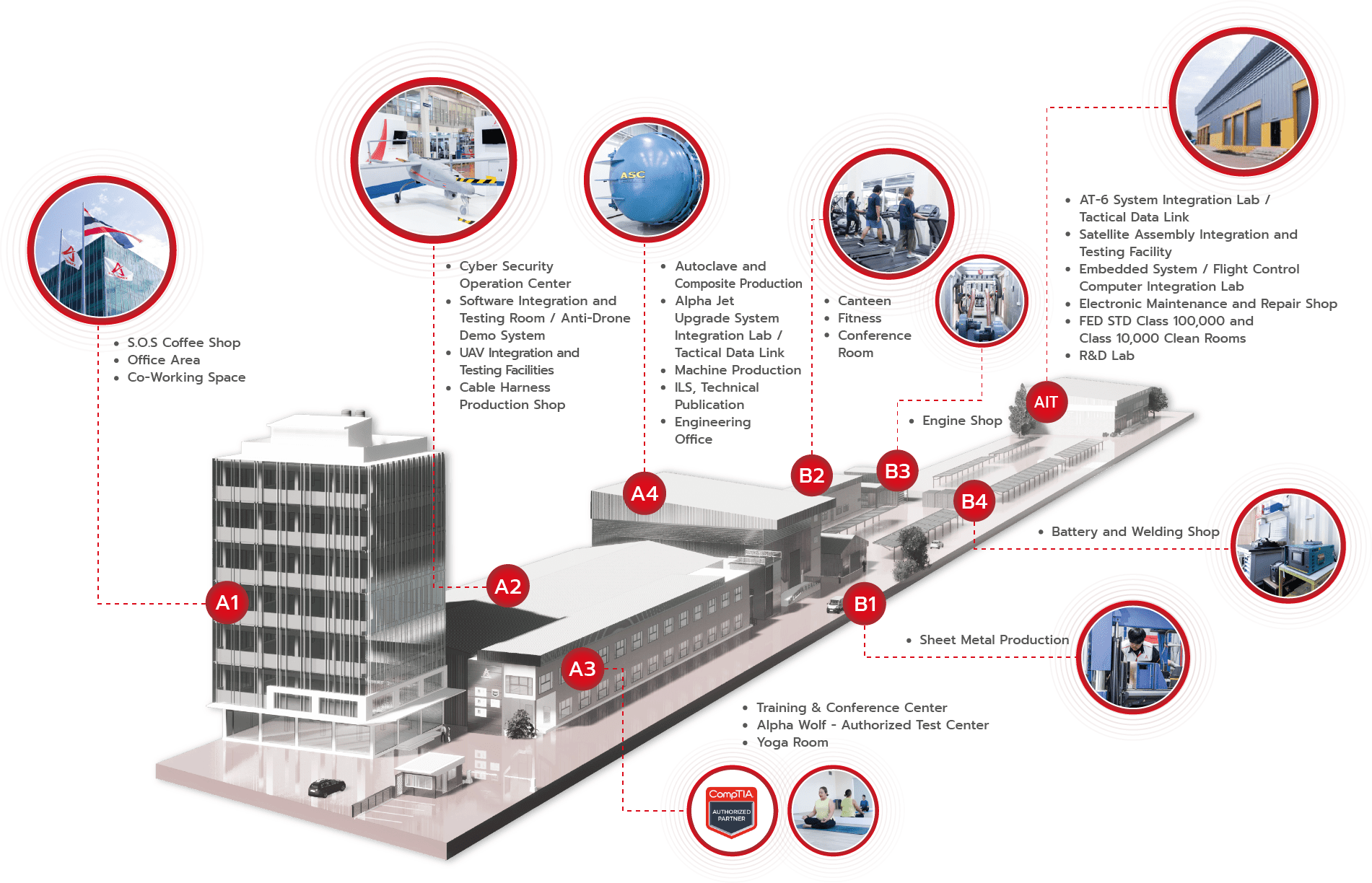

Deep-Tech Innovation Center

RV Connex Facility

The A2 Building is a premier facility designed to support a wide range of engineering operations. It houses advanced production and testing capabilities for cable and wire harnesses, electronics, and communication equipment. The building also features a state-of-the-art data center equipped with high-performance computing for complex aerodynamic and structural integrity calculations. Key facilities include a Cyber Security Operation Center, a Software Integration and Testing Room, UAV Integration and Testing Facilities, and a dedicated production area for Anti-Drone Systems.

The A3 Building is home to the Alpha Wolf PearsonVUE Certified Test Center, authorized to administer industry-leading certification exams certified by leading institutions such as Microsoft, Cisco, AWS, CompTIA, and more. Specializing in Cybersecurity and Information Technology (IT), the facility offers comprehensive training and certification programs from foundation to professional levels. Additionally, the A3 Building features a modern Training & Conference Center, complemented by a Yoga Room for wellness and relaxation.

Alpha WolfThe A4 Building is a hub of advanced engineering excellence, dedicated to precision metal works and cutting-edge systems integration. Within its walls, the top-tier Systems Integration Lab (SIL) drives innovation, supporting critical projects like the Alpha Jet Upgrade System Integration Lab with Tactical Data Link capabilities. The facility also houses specialized autoclave and composite production areas, along with high-precision machine production units. Complementing these technical spaces, a well-appointed engineering office fosters collaboration and the development of pioneering solutions.

The B1 Building is a specialized facility dedicated to the production of sheet metal components for the aircraft industry. Equipped with state-of-the-art machinery and advanced fabrication techniques, RV Connex rigorously adheres to international standards, ensuring airworthiness and safety in every component. This facility plays a crucial role in aircraft upgrades and modifications, delivering precision-crafted parts that meet stringent aerospace engineering demands and support the evolving needs of the aviation sector.

The B2 Building offers essential amenities including a canteen, a fitness center, and a versatile conference room for events, meetings, and functions. These facilities enhance the work environment, supporting both employee wellness and organizational activities.

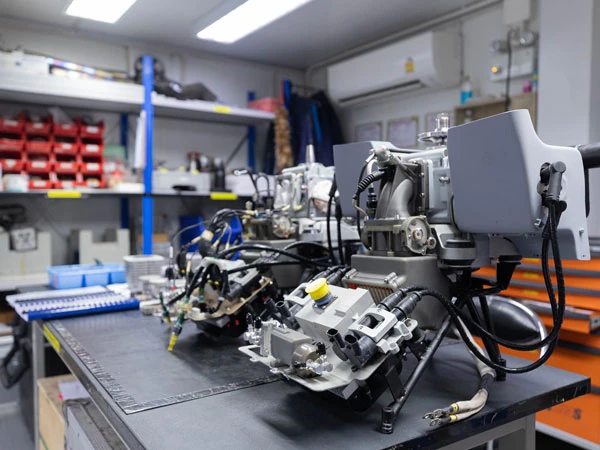

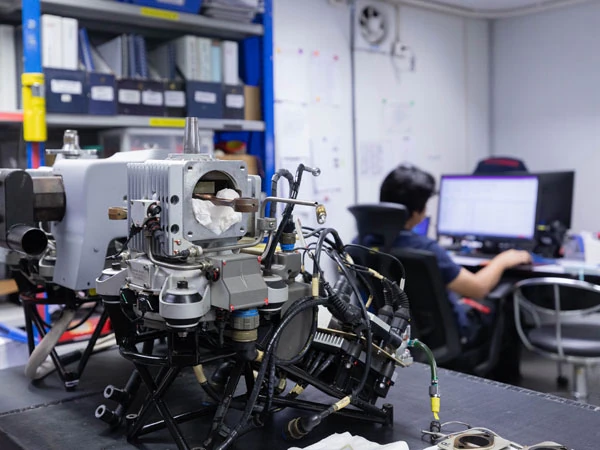

The B3 Building is dedicated to advanced engine testing and maintenance, featuring a state-of-the-art Engine Test Cell and a fully equipped Engine Shop. The Engine Test Cell is designed for comprehensive performance evaluation and validation, ensuring optimal engine functionality and reliability. The Engine Shop supports precise repairs and overhauls, maintaining the highest standards of quality and performance for our aerospace components.

The B4 Building specializes in battery production and precision welding. It features advanced technology for high-efficiency battery manufacturing and state-of-the-art equipment for durable metal joining, ensuring top-quality components and systems.

The Assembly Integration & Testing (AIT) Building is a premier facility dedicated to the advanced production of satellite components. It boasts FED STD Class 100,000 and Class 10,000 clean rooms, ensuring optimal conditions for critical assembly and integration processes. The building houses an Optical System Test Facility for precision testing, a High-Frequency Radio Signal Communication Development Room, and a comprehensive Electronic Manufacturing and Testing Room that meets global satellite standards. It also features an Embedded System/Flight Control Computer Integration Lab and a Surface Mount Technology (SMT) production line for meticulous PCB assembly. This state-of-the-art environment supports innovative R&D, precise engineering model development, and high-quality electronic circuit board production, driving progress in satellite technology.

Metal Sheet and Composite Material Production

Autoclave

Coordinate Measurement Machine (CMM)

5-Axis Computer Numerical Control (CNC) Swivel Head and Rotary Table

Wire and Cable Harness Production

Laser Wire Marking

Wire Stripper

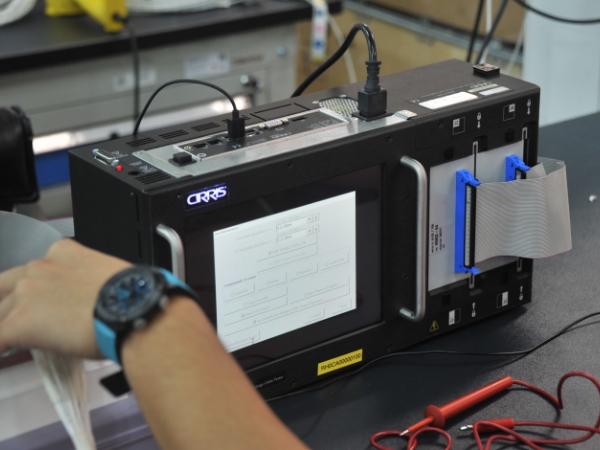

Cable Tester

Software Tools

Metal Sheet and Composite Material Production